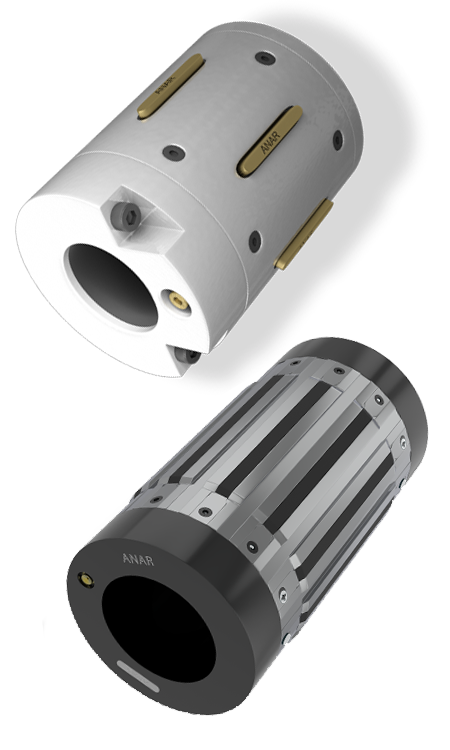

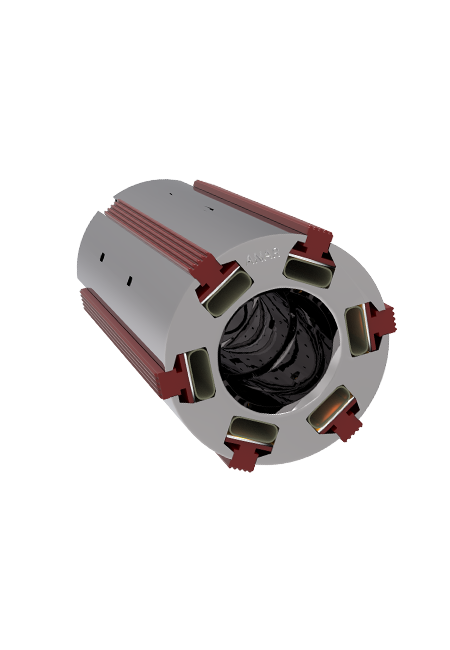

CORE AIR SHAFT

Core shafts are used to unwind or rewind web materials in shafted winding processes. The winding shafts can expand to grip the diameter of the core, allowing it to control web tension.

- Carbon fiber shafts come with an air valve made from stainless steel, not corroded.

- Simple-access journal fastening mechanism (no pressing for the correct size).

- Grips the lugs.

- Proprietary corded bladder material made helps of prevent bladder failure and maintenance.

- Carbon fiber shaft housings can offer strength and stiffness similar to steel but at less weight.

- Metal sleeves protect carbon fiber shaft housings from scratches.

- Custom-designed journals of steel made to fit the requirements of any machine.

Core Air Shaft Types

Mechanical core shafts and mandrels are mechanically-expanding products that feature a continuous lug of leaf. They expand in a concentrated manner and are different in both design and the style of mounting. Mechanical shafts are able to provide roll-centering and positive expansion as well as contraction with a uniform diameter. The low-maintenance core shafts as well as mandrels are ideal for high-speed applications and high-tension.

There are numerous different types of mandrels and shafts for cores. Examples include:

Standard air Shafts

Internal Bladder-type Shafts

External element Air Shafts

Mill Shafts

Aluminum and lightweight composite extrusion Shafts

Differential Air Shafts

Slitter Shafts

Core Air Shaft Features

Mechanical core shafts and mandrels are mechanically-expanding products that feature a continuous Shaft. They expand in a concentrated manner and are different in terms of design and style of mounting. Mechanical shafts can provide roll-centering and positive expansion and contraction with an even diameter. The low-maintenance core shafts and mandrels can be used for high-speed and high-tension use. When choosing a mechanical lug-style shaft face length, the face's length and the construction materials are vital aspects to be considered. The face length typically will be in mm. The materials used for shafts include aluminum, steel, and carbon-based lightweight. Mandrels and core shafts powered by air are a part of standard airshafts: internal bladder-type shafts and external air shafts with elements. There are numerous types of air shafts that are used for winding, unwinding, and winding rewinding. Standard air shafts include leaf shafts, mechanical lug shafts pneumatic or air-powered shafts for lugs buttons shafts, as well as pad shafts. The label press shafts were explicitly designed to be used in narrow-web converters. Leaf shafts are employed for winding. Button air shafts are offered for light-duty as well as medium-duty applications. When choosing the suitable core shafts and mandrels, their inner diameter (ID) is a crucial feature to be considered. Mandrels and Core shafts make up external air shafts, the light shafts and differential shafts and the slitter shafts. Air shafts with external elements can be employed in numerous rewinding and unwinding processes. Some of them have a spiral element. Lightweight shafts are generally constructed from aluminum or other low-cost composite materials. Internal body shafts with composite body feature pads or mechanical lug designs. Slitter and air shafts that are differential are available. The mandrels and core shafts are utilized in the film, paper, and foil manufacturing.